JB-2010 High-power rebar upset forging parallel threading machine 12-40mm

The earliest application project is Dubai metro red line , this project adopt 40mm rebar connection , the main size is 40mm and 32mm rebar connection , the tensile strength of rebar is higher than 800Mpa , yield strength is 600Mpa.

The clients require the min tensile strength of our coupler connection reach 800Mpa, the actual test value should reach 1000Mpa , we customize two products according to their requests :

1. High power upset forging parallel threading machine , it is suitable for connecting rebar from 12-40mm , the best working range is process rebar from 32mm to 40mm , For upset forging machine , we use higher pressure cylinder, accelerate speed and power rate during processing 40mm rebar , for threading machine , we accelerate the speed and enlarge the power during threading process

JB-2010 High power rebar upset forging parallel threading machine JB-2010 High power rebar threading machine

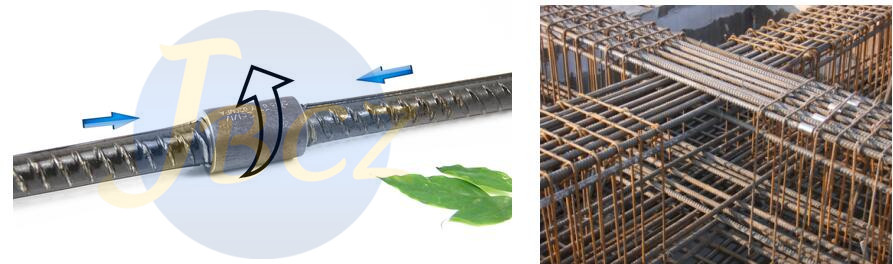

The comparison picture between parent rebar and rebar after upset forging The comparison picture between the thread after upset forging and parent rebar

We have superior high strength coupler to match with the rebars , the tensile strength is higher than 800Mpa , the yield strength is higher than 600Mpa. More information about superior coupler , please click below picture .

Test result: JBCZ upset forging parallel thread connection is 100% higher than steel bar material strength , rebar connection belongs to the world’s highest standard requirements, satisfy: American ACI-318, British BS4449, France and other world’s highest quality inspection.

I There are many types of connection , satisfy each connection request on job site:

Standard type, this connection type is suitable for 80% projects.

II.Reducing rebar coupler connection, suitable for the change between story , for example , the basement adopt 32mm rebar , the story use 25mm rebar , it need reducing coupler in this situation ,

one end connect 32mm , another end connect 25mm , satisfy rebar connection in different sizes.

III.Adding length coupler connection , this type of connection suitable for the situation that two reinforcing bars can’t be rotated , such as the rebar cage connection at job site ,

both of the rebars can’t be rotated, then this type of connection is the most suitable one.

First step , screw the full coupler onto the first bar

Second step , screw back the coupler onto the second bar

Third step , finish the connection

Ⅳ.Left and right hand coupler connection , this type is suitable for the project that two rebars or one rebar can’t be rotated , the advantage is only need to rotate the coupler can finish the connection of two rebars.

One end of rebar thread is right hand , the other end of rebar thread is left hand , the rebar thread match with coupler, tighten two rebars while rotate the coupler , the coupler size : 12mm to 40mm rebar connection range.

Ⅴ.Adding length with nut connection , it is the same principle as adding length coupler connection , suitable for connecting two reinforcing bars which can’t be rotated, use the nut to fix the coupler make it can’t move up and down.

Ⅵ.Terminal coupler connection , this type is suitable for the embed project such as embedded column, wall embedded, all need this type , during the embedded , in order to prevent the concrete poured, each coupler will with one plastic cover to protect the thread of coupler . Product size satisfy : 12mm to 40mm rebar connection range.

VII.Terminal coupler connection , this type is suitable for the embed project such as embedded column, wall embedded, all need this type , during the embedded , in order to prevent the concrete poured, each coupler will with one plastic cover to protect the thread of coupler . Product size satisfy : 12mm to 40mm rebar connection range.

VIII.Half thread half press coupler connection , this type connection is suitable for the situation that one end of rebar has already poured into concrete and can’t be rotated. Product size satisfy: 12mm to 40mm rebar connection range.

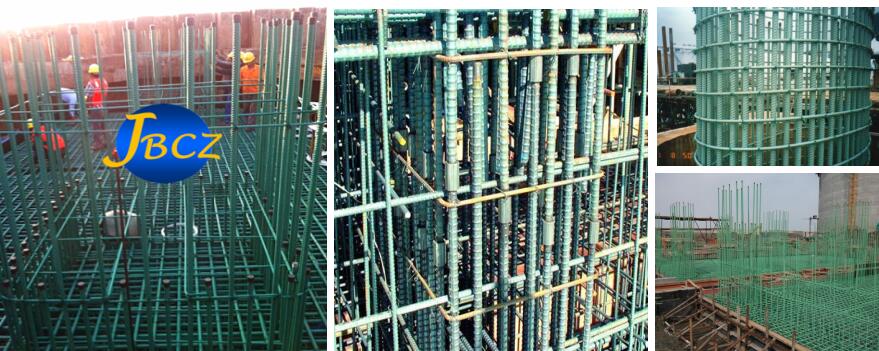

VVI.Epoxy coated rebar connection . Epoxy couplers have been applied in the world’s first longest bridge—Hangzhou Bay Crossing Sea bridge , The world’s second largest water pump station in Jeddah , Saudi Arabia.

Real application pictures in rebar thread job site.

The big power upest forging parallel threading machine and high tensile strength coupler have been applied in Dubai metro

Dubai shopping mall Capital airport in Beijing